Back

STONE CHIP GRINDING WASHING & DRYING PLANT (120pro)

Price (excl GST): POA

Make: Joyal

Motor: 3ph, LPG

Condition: v good

Location: New Zealand

Output: upto 15,000kg/hr

On offer is this used / secondhand stone chip grinding, washing and drying plant. The seller who provided the advertisement details has outlined: Items may be a couple of years old, it is in very good condition as it has only been used to run tests to ensure it operates to specification, so not much use at all. Offered within the scope of equipment is:

Grinding and washing plant comprises:

Hopper & feeder

First chip conveyor

Hammer mill (capacity 8 to 15 tonnes per hour)

Steel frame for hammer mill

Second conveyor

Twin deck wash screen

Wash pump

Hoses and fittings

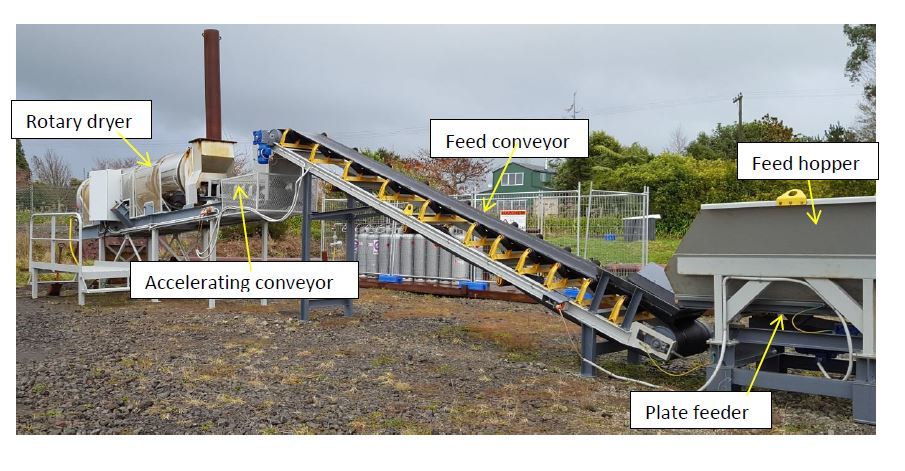

Drying plant comprises:

Hopper

Feed conveyor

Accelerating conveyor

Dryer rotary gas fired (capacity 3 to 4 tonnes per hour input)

Discharge chute and frame

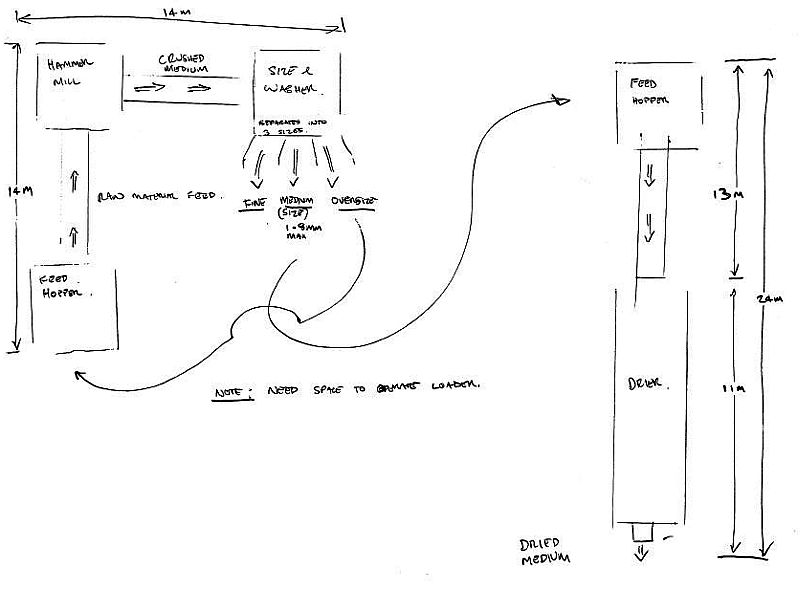

The Chip plant is designed in two parts:

1. Grinding raw material, max size 30mm down to 70 to 80% <2mm. We will do this by loading the raw material into a hopper feeder that will control the amount onto a conveyor belt that will feed the material up into the hammer mill, (If the product is over 10-15% in moisture content then it will have to go through the dryer first) then the sized product will discharge out the bottom of the hammer mill onto the second conveyor which will feed the product onto the screen to be washed and sized into sand and chip for the tiles. The two products will fall under the screen into concrete bins that the screen will be positioned on.

2. Drying either the raw material before grinding or drying the chip to the required moisture for applying to the tiles. We’ll do this by loading the product into a hopper that has a conveyor controlling the amount of product going to the rotary dryer and then a small conveyor running faster feeding the product into the dryer, we have sized the dryer to run at 3 to 4 ton/hr input. The product then discharges out of the end of the dryer onto the ground or customer supplied hopper ready for bagging as soon as it is cool enough.

The line is designed so that the two systems are separate and can be running at the same time or just on their own, depending on production. The grinder requires the stone not to be more that 10-15% moisture content when entering the grinder.

Grinding and washing specification:

Hammer mill

Model: Joyal PC4008, 45Kw motor

Maximum feed size 30mm

Maximum stone moisture content less than 10-15%

Output material finest to 70 to 80% less than 2mm

Capacity 8 to 15 tonnes per hour

Rotary Dryer specification

Capacity 3 to 4 tonnes per hour (input)

Fitted with LPG burner

An independent inspection and report of the equipment is available upon request. The assessment of the grinding and washing plant was performed on the 28th March 2017 and determined that all of the listed equipment was present at the time of my inspection. The plant was run for approximately 1.5 hours and I estimated that the throughput was well within the required rate of 8 to 15 tonnes per hour. The output was checked visually and estimated to be within the 70 to 80% minus 2mm. The drying plant was then run for an hour and checked to ensure compliance with the acceptance testing criteria and found to pass all of the required testing criteria. The plant was run for 1/2 hour with the 2mm feed material and the input was within the required rate of 3 to 4 tonnes per hour.