Back

APPLE PROCESSSING LINE (137pro)

Price (excl GST): $100,000

Make: ABL, Urschel etc

Motor: 3ph, air

Condition: good

Location: New Zealand

On offer is this used / secondhand apple processing line. The seller who provided the advertisement details has outlined: The processing line was last used in 2016. It produces diced apple, using a "hot-fill" process. Output is 4500 kilograms of finished product per 8 hour shift. The product is packaged into 15kg or 5kg high oxygen barrier pouches. These pouches can be stored at ambient temperature for up to 14 months, which enables a 12 month sales window. The process uses no added preservatives, relying instead on the de-aeration and heating of the product to stabilise it.

The line is automated and requires only two process workers and one operator to run. The product was mainly sold to the foodservice sector for the onward manufacture of various apple baking products, i.e. apple pies, turnovers, etc. Also a second product produced was a cinnamon based diced apple, which was used in fruit stick manufacturing for the export market. The shed it is in now is 30 x 12m, it has quite a bit of wasted space, so could be smaller. The present owner is willing to offer advice to any new owner on set-up and commissioning of the plant.

Apple Processing Line Main Assets:

1- Stainless Steel Water Dump c/w motorised leaf removal screen, circulation pump & water dump bin forks.

2- Apple sizer conveyor, for sizing apples into large, medium or small sizes.

3- Automatic apple peeling/coring machines, two (2x) of ABL peeling machines, model PDS RTT100, c/w in feed tanks, singulators, orientators, peel/core reject conveyor & elevator. Plus 1xABL peeler suitable for parts. Plus range of various spare parts for above machines.

4- Peeler out feed conveyors, elevator & fluming

5- Fines removal shaker & fines reject system (SOLD)

6- Transfer pump and fluming

7- Deaeration Tank System, 3 x automatic vacuum tanks, PLC controlled, c/w associated walkways & additive tank

8- Final inspection out feed conveyor & elevator

9- Hydraulic solids transfer pump c/w hydraulic power pack

10- Heat exchanger c/w metal detector

11- Automatic Bag Filler c/w load cells, nitrogen purge & out feed conveyor (SOLD)

12- Cooling Tank, 13m x 2.5m x 1m c/w bag in feed conveyor, rod out feed conveyor, circulating pump, air knife bag dryer & cooling tower

Ancillary Equipment:

Air compressor, Ashair CPB 15, screw type.

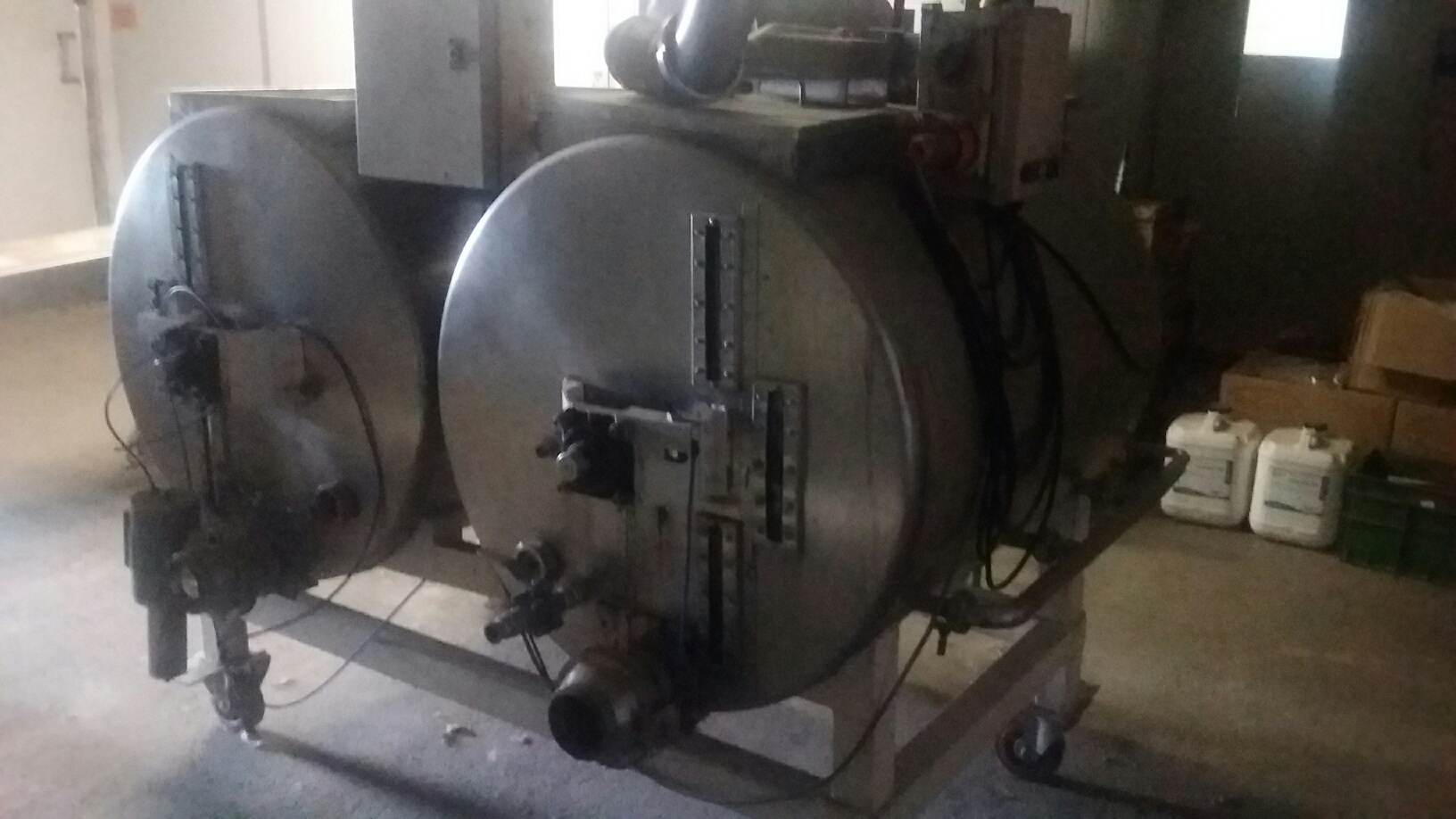

Twin Blending Tanks for cinnamon product.

Carton Taping machine.

Main electrical control system (PLC controlled) c/w electrical cables, etc.

Extra's included in the sale are:

Food safety programme for "Hot-fill Diced Apple" Product

List of supplier contacts and costings Machinery manuals and maintenance records.

For YouTube clip of plant in operation please click the following video link:

www.youtube.com/watch?v=qs6AX2VSJ1M&;t=19s