Air Compressors

Bakery

Dividers, Moulders

Other

Ovens

Tins, Trays, Racks

Boilers

Burners, Heaters

Hot Water

Steam

Canning

Centrifuges

Citrus Peeling Line

Cleaners, Washers

Other

Product

Confectionery

Conveyors

Belt

Bucket Elevators

Other

Roller

Screws, Augers

Cookers

Blanchers

Cookers, Hoods

Fryers

Pans, Self Generating

Pans, Steam Water

Retorts, Autoclaves

Crisp Production Line

Dairy

Drives, Motors

Dryers

Engineering

Fans, Blowers

Fillers, Cappers

Cappers

Other

Piston Depositors

Filters

Forklifts

Fruit Processing

Grinders, Crushers

Heat Exchangers

Homogenisers

Horticultural

Laboratory

Meat, Fish

Extruders

Injectors

Massagers

Mincers

Other

Saws

Slicers, Dicers, Filleters

Smokers

Metal Detectors

Milling

Miscellaneous

Mixers

Other

Planetary

Ribbon

Spiral

Tumble

Packing

Carton

Flow Wrappers

Labellers

Other

Sealers

Shrink

Vacuum Packers

VFFS

Pasta

Peelers

Plate Freezer Plant

Processing Lines

Product Displays

Ambient, Heated

Refrigerated

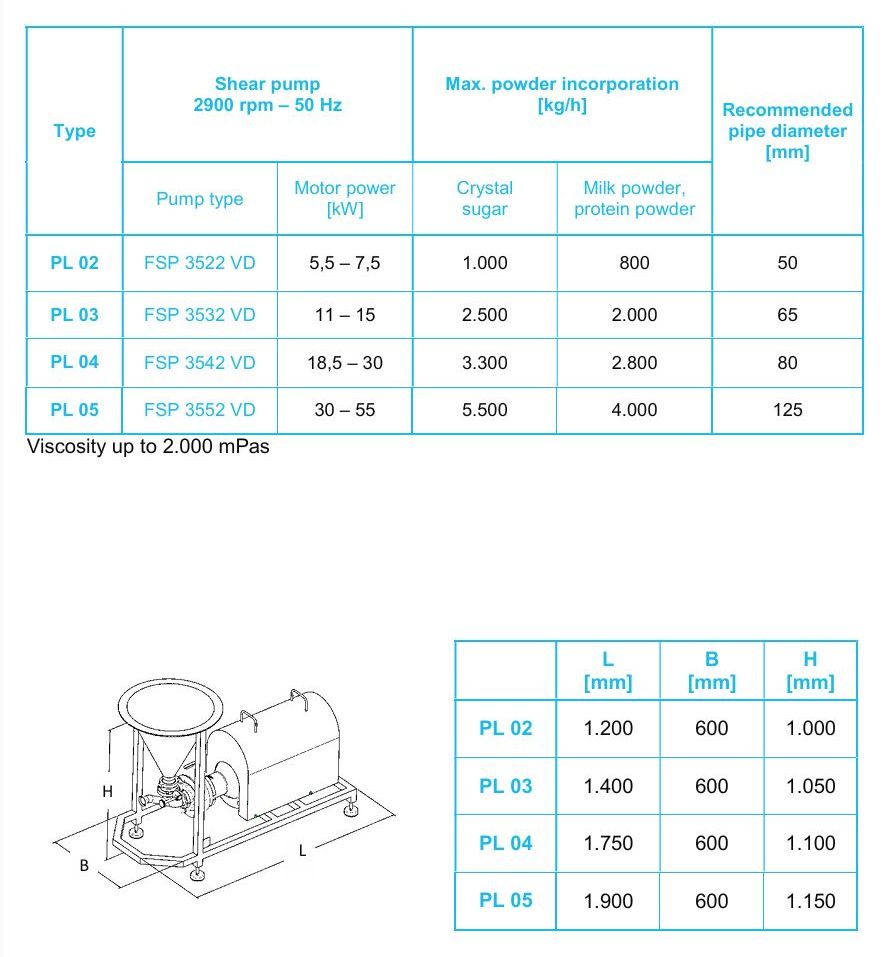

Pumps

Centrifugal

Other

Refrigeration

Compressor Plant

Ice Makers

Other

Roading Earthmoving

Sawmilling

Scales, Weighers

Shop Fittings

Sifters, Screens

Slicers, Dicers, Cutters

Tables, Shelves

Tanks, Hoppers, Vats

over 2,000L

up to 2,000L

Valves

Weighing Bagging Line

Wine, Juice, Beer

|