Back

ROTARY PISTON FILLERS/DEPOSITORS (193fip)

Price (excl GST): POA

Make: Hunter

Model No: 2000 Series

Motor: air

Condition: New

Location: New Zealand

Capacity: up to 1000ml

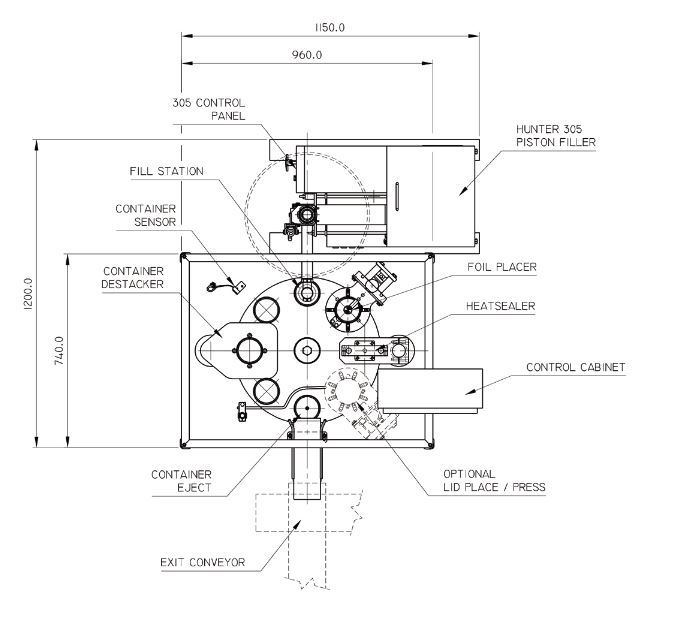

These NEW 2000 series units are a fully automatic single track intermittent motion 8 station rotary filling and lidding machine designed to handle a wide range of stackable (round or rectangular) tubs, generally up to 1kg / 1 litre capacity. Output may be up to 65 containers per minute depending on product type and container size.

Two main variants are available (2001 or 2001-2) - the major difference being that the 2001-2 incorporates mechanisms to apply a heat sealed foil membrane and a clip-on over lid, while the basic 2001 can only apply one or the other.

Construction is generally corrosion resistant - type 304 stainless steel is used for all framework, external sheathing and control enclosures - type 316 stainless steel for product contact parts on the filling head. Turntable drive is mechanical - via a hydraulic drive incorporating overload protection. Container and lid handing functions are cam actuated with some pneumatic assistance. Systems for liquid or semi-liquid products generally incorporate a pneumatically operated piston filler (with bottom-up fill if necessary).

Microprocessor (PLC) control of all functions ensures exceptional reliability and together with numerous solid state sensing devices, provides many interlocks and safeguards including the standard no container/no fill and no container/no lid features on all machines.

A wide range of container sizes (up to 150.0mm max dimension) can be accommodated by the use of change parts - change over time is usually no more than 15 to 20 minutes.

Special purpose machinery and ancillary equipment may also be provided as required.

Any or all of the following facilities may be incorporated:

• Container destacking

• Filling: various units available for most applications

• Membrane placing and (heat) sealing

• Lid (clip on) placing and closing

• Ejection: to (optional) out-feed conveyor

• Date coding

Features include:

• 8 Station rotary indexing machine for filling sealing, and lidding of round or rectangular tubs,

• Upto 60 tubs / min filling and lidding and upto 35 tubs / min filling and heat seal membrane,

• Systems often incorporate Hunter volumetric fillers (model 305 or model 505),

• Microprocessor (PLC) control on all functions ensures exceptional reliability,

• Standard no container / no fill and no container / no lid features,

• Safety guarding and interlock to appropriate standards,

• Optional bottom-down fill (container lift) at 2 filling stations,

• Change parts available for different sized containers and lids,

• Stand up pouch version available for filling and sealing of gusset type bags.

Products currently being packed by Hunter fillers include:

Foodstuffs:

Butter, margarine, processed cheese, yoghurt, yeast extracts, pate, jams, stews, bread dough, sauces, mayonnaise and salad dressings, peanut butter, honey, chutneys and pickles, cooking oils, fruit juices, cordials, toppings and flavourings.

Cosmetics:

Lotions, shampoos, conditioners, nail varnishes and various creams.

Other:

Detergents, disinfectants, bleaches, motor oils, printing inks, epoxy resins, paints, adhesives, caulking compounds, weed killers, garden & agricultural chemicals, veterinary and ethical supplies.