Back

RACKING (394ts)

Price (excl GST): POA

Condition: New

Location: New Zealand

Material: steel

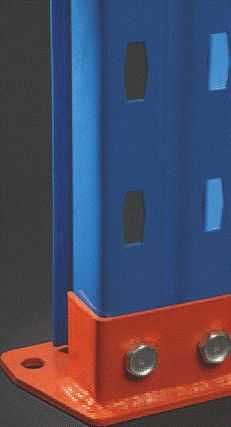

This pallet racking range on offer is a good quality and excellent value. It is ideal for industrial and commercial sites where heavy-duty pallet racking is needed. Built to exacting quality and safety standards, and seismic ratings, this system provides great value for customers needing to store heavy items across forklift-accessible racking spans. The section profile is strong - offering extra rigidity, and the feet provide great support with two bolts for fixing to the floor which helps to resist forklift impact damage. Many existing pallet racking systems use beams that will fit this systems uprights; however these beams will not fit the uprights found in existing systems.

- Sturdy steel pallet racking design

- Easy to assemble

- 5 year guarantee and ISO 9002 accredited

- Full epoxy powder coated finish

- Red / Blue colours stocked, others available

- Galvanised options for coolrooms and freezers available on indent

- Particle board or ply shelves available

- Large range of accessories and frame/beam sizes available

- 8-10 weeks delivery on larger or indent orders

The frames are rated to take 8 tonne with a 1.83-1 safety factor. Pressure test results - 109kN of pressure per post, or 11 tonnes

Standard Frame:

Depth: 900

Loading capacity: 8000kg

Section size: 80mm x 70mm x 2mm

Height: 2100mm, 2400mm, 3000mm, 3600mm, 4200mm, 4800mm, 5400mm, 5850mm

Standard Beams:

Loading capacity: 2300kg

Section size: 100mm x 40mm x 1.5mm

Length: 1350mm, 1800mm, 2100mm, 2400mm, 2700mm

Row Spacer 200mm / 300mm

This style of shelving can be produced and installed to meet many different racking requirements. Please note that the maximum height designed to is 11m. Special applications include the following:

Double Deep

This option is typically selected where stock selectivity is less important, but storage space is at a premium. As the name suggests, the pallets are stored two bays deep (basically two pallet racking bays are connected back to back instead of spaced apart). This is an economical way of increasing storage space, but the rear pallets have to be accessed using specially designed forklifts that can reach two bays deep. This system is limited to two deep because of ‘reach truck’ capacity.

Double Deep Push Back

This option is similar to double deep except there is a special push back mechanism fitted to the bays to enable the front pallet to be pushed-back. This eliminates the need for special forklifts, and can go several pallets deep. The pallets are on rollers so when the front one is removed the rest roll forward.

Drive In

This option is typically selected where there is fast turnaround of large amounts of stock, required on an infrequent basis (such as seasonal stock). There are no cross-beams used, instead the frame width is increased and forklifts can drive between a frame and pick a pallet that is sitting on continuous rails. Drive-in configurations are more suited where individual selection is less important, stock movement schedules are consistent and the stock range is small. This system provides excellent space utilisation; up to twice the number of pallets can be stored in the same space occupied by normal pallet racking systems. Standard forklifts can be used with this first-in, last-out option.

Mobile Racking

This option is typically selected where storage space is extremely limited and stock throughput is low. These mobile racks actually run on steel rails, allowing a whole bay to be moved electrically to enable access to stock. As a great deal of weight is being moved the speed of stock transfer is slower than other types of systems, however space saving is immense and forklift running costs lower. Special design drawings are required to get the space allocation and electrical motor loadings correct. This system is often used in coolrooms to get maximum space utilisation and stock accessibility.

Flow Through

This option is typically selected where similar stocked pallets experience fast stock turnaround. As the name suggests, the pallets flow along sloped conveyor lanes consisting of a series of glide wheels. Stock travels along the slope, from the highest point to the lowest point. The rate of movement is determined by the angle of the slope and speed is controlled using centrifugal brakes. This system provides excellent space utilisation and reduces the distances travelled by forklifts. Standard forklifts can be used with this first-in, first-out option.

Multi Tier with Raised Storage

This option is typically selected where an additional floor is required above the nominated storage space. This system is basically pallet racking or long span shelving spaced according to the load requirements of the floor above. Different floor types can be used. We recommend steel mesh as this is likely to comply with the existing sprinkler system allowing water access to all storage areas and light to be filtered through to lower goods. Solid wooden floors are acceptable when sprinkler systems and lighting can be deployed to the lower storage level. The supplier requires detailed design drawings and loading characteristics to ensure the construction complies with safety requirements. This system is ideal for hand loaded shelving such as spare parts or document storage.

CANTILEVER shelving is also available and is a good quality, excellent value, shelving system. It is ideal for Industrial and Commercial sites where cantilever shelving is needed (as normal racking systems impede the access of longer products due to uprights).

Built to exacting quality and safety standards, they provide great value for customers needing to store long items. The section profile is excellent offering extra rigidity, the out-riggers are adjustable at 90mm increments which makes the whole system very versatile.

- Huge range of configurations/sizes available

- Sturdy steel cantilever design

- Easy to assemble

- 5 year guarantee and ISO 9002 accredited

- Full epoxy powder coated finish

- Red / Blue colours stocked, others available

- 8 weeks delivery on indent orders

- Out-rigger clip-on and adjustable at 90mm increments

- Loading to suit client requirements

Upright Depth: 900mm

Upright Height: 2000mm

Upright Loading capacity: 8000kg

Upright Section size: 180mm x 50mm x 3mm

Base Depth: 930mm

Base Length: 1200mm

Base Section size: 180mm x 50mm x 3mm

Support Arm Length: 750mm

Support Arm Loading capacity: 400kgs

Connector Arm Length: 1650mm

RAISED FLOOR RACKING - This is essentially a mezzanine option, whereby a second internal floor is required. Different step designs and barriers can be included in accordance with instructions. The supplier requires detailed design drawings and loading characteristics to ensure the construction complies with safety requirements.

Raised floors are available in increments of 3600mm, 154.3 kgs per m²

Floor Area

3600mm x 3600mm = 12.96sqm (2000 kgs)

3600mm x 4400mm = 15.84sqm (2400 kgs)

4400mm x 4400mm = 19.36sqm (3000 kgs)

3600mm x 6200mm = 22.32sqm (3400 kgs)

4400mm x 6200mm = 27.28sqm (4200 kgs)

6200mm x 6200mm = 38.44sqm (5900 kgs)

3600mm x 8000mm = 28.8sqm (4400 kgs)

4400mm x 8000mm = 35.2sqm (5400 kgs)

6200mm x 8000mm = 49.6sqm (7700 kgs)

8000mm x 8000mm = 64sqm (9900 kgs)

(Further sizes are available)