Back

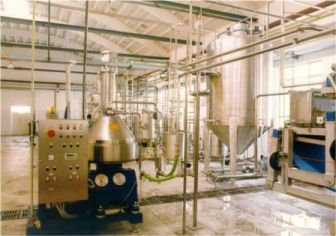

PINEAPPLE PROCESSING LINES (020pro)

Price (excl GST): POA

Motor: 3ph

Condition: New

Location: Italy

This manufacturer has developed a highly specialised technology for pineapple processing into juice and concentrate. The juice and pulp extractor is suitable for round and ripe pineapples without tips at a rate of 4 to 4.5 tons per hour. The treatment is effected in hygienic conditions, as the juice and the pulp do not come in contact with the peel. The machine cuts the fruit in two halves, squeezes and scrapes the pulp adherent to the peel and eliminates the peel thus obtaining a good quality pulpy juice, in high hygienic conditions. The fruits are conveyed to the loading hopper and are led to the centring group which pushes them against the rotating blade thus obtaining a diametrical cut. The half fruits fall down in the centre of two rollers and are driven by the squeezing roller against the grid with large dimensioned holes, allowing an easy yield of the juice. The exhausted peels are then taken by a third toothed drum which removes all pulp still adherent to the peel, before eliminating the same. The unit has many adjusting possibilities. The squeezing grid can be closed or parted in order to achieve an ideal juice yield. The peel squeezing device can be adjusted as to obtain thickness of 2-3 mm and also 5-6 mm according to the consistency and thickness of the peel.

The unit has:

rotating centring mechanisms with elastic grooves; distance adjustable according to the size of the fruit,

rotating blade with special profile,

shoots directing the half-fruits,

two drums, one for the inlet of the fruits and the other for the squeezing process,

squeezing grid with large holes, supported by a mobile structure, operated by a pneumatic piston allowing a fast opening during cleaning operations,

rotating toothed drum to drive the peels against the blade, separating and cutting the pulp remaining adhered after squeezing,

two chutes, one for the collection of peels to be eliminated and the other one for the collection of juice and pulp,

motor drive with gears in oil bath, gears and transmission chain,

supporting structure in carbon steel protected with a double coat of anti-acid sanitary paint,

centralised lubricating group for conveying grease to the supports of mechanical devices,

centralised group for washing of the machine in operation.

All parts in contact with the product are manufactured in stainless steel Aisi 304, with the exclusion of some parts manufactured in bronze, rubber, Teflon or other sanitary materials due to manufacturing and processing purposes.

Also available for the processing of this fruit include RECEIVING, WASHING, SORTING & SIZING equipment. Fresh Pineapples are received in bulk or cases and fed to the plant from an outside concrete tank, filled with water. Hence sorting and immersion bath systems are available. Also available is a peel shaker for additional juice recovery.

The PINETRONIC is a dedicated pineapple extractor which cuts the fruit in two halves, extracts the juice and pulp and eliminates the peel while obtaining a pulpy juice of excellent quality. No contact between juice and peel takes place.

DEPULPING / REFINING is via a Helicoidal extractor model ESM. Also available are decanters or centrifuges which can be used to further reduce the pulp content.

PEEL PRESSING in order to increase the yield of the line, is possible with a BELT PRESS, which recovers the remaining juice from the peels coming from the Pinetronic.

Also available are CONCENTRATORS such as a plate evaporator for the treatment of low viscosity juices and according to the requirements the unit can be equipped with AROMA RECOVERY.

STERILISATION equipment can also be supplied via plate sterilisers designed for the sterilisation of low viscosity products such as concentrated juices along with ASEPTIC FILLING via the C.A.F. (Compact Aseptic Filler) either in the single or double head filler designed for the filling of 3 to 20 litre bags. The machine is equipped with an aseptic buffer tank and also available is an option to also fill into 200 litre bags in drums.