Back

ORANGE GRAPEFRUIT & LEMON PEELERS (040fr)

Price (excl GST): POA

Length: 1400/1500

Width: 1300/1600

Height: 1900

Motor: 0.37kW & 0.75kW, air

Condition: New

Location: Italy

Output: 15-44/min

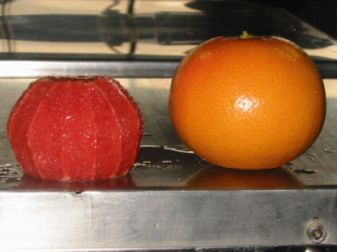

This machine was especially designed to thoroughly peel oranges, grapefruit and lemons for fruit salad and marmalade production.

The units require a single operator and comes in 2 differing models (capacities can vary dependent on the fruit shape and firmness):

2 head unit is rated an output capacity of 15 to 22 pieces/minute,

4 head model which is rated an output capacity of 30 to 44 pieces/minute.

This machine completely removes the zest and pith from citrus fruit and adjusting the peeling depth is available according to fruit type and production requirements. The peel moreover slips down through a special outlet system with no contact and contamination between the peel and eventually the cores, on the one side, and the peeled product, on the other. This machine is available with or without coring function.

The machine main frame and all safety guards are made of AISI 304 stainless steel. All parts coming into contact with fruit are made of AISI 304/316 stainless steel and food-grade plastic. The fruit peeling blades are located in the central area of the machine. All peeling elements may be adjusted according to the required peel thickness to be removed from fruit.

Core size may as well be adjusted thanks to interchangeable core tubes ranging from 15 to 18mm in diameter.

Safety devices complying with EC standards include double light barriers or sensors and IP67 micro switches. All safety guards may be easily removed thanks to quickly releasable interlocked hinges. This allows easy, quick and safe maintenance as well as thorough cleaning. The machine operates with each piece of fruit being positioned by the operator inside a holding cup where it is fastened by a special clamping device. The carriage supporting the fruit holding cups starts moving towards the blades, while tilting the cups by 90 degrees. Fruits are thus brought into a horizontal position. At the end of the carriage stroke, each piece of fruit is transferred onto the peeling and, eventually, coring heads and then start rotating while the blades, thanks to the special profile cam they are connected to, move along their shape and peel them by gently touching their surfaces. At the end of the operating cycle, fruits are dropped on the discharge system (not included). The standard model of this machine is equipped with a flap system separating fruit peel and cores from peeled fruit.

Can come with the following optionals:

CORING: where upon customers demand, the machine may be supplied with a coring system.

TOPPING AND TAILING: where upon customers demand, the machine may also be supplied with special blades for topping and tailing.

DISCHARGE SYSTEM: where upon customers demand the machine may be equipped with either of two possible discharge systems. One consists in two conveyor belts carrying peeled fruit and wastes to the two opposite sides of the machine, this system is not suitable for machines with topping-and-tailing functions. The other system consists in a two-roller system conveying peeled fruit out of the machine while fruit peel and wastes pass in between the two rollers and fall onto a conveyor belt carrying them into a collecting container.

The unit requires electrical power supply of 0.37kW and 0.75kW required for both models.

Both models require a source of compressed air of 4 atm (58.78 psi).

The dimensions specified show the 2 head units dimensions to the left, and the 4 head unit to the right.

To view this style peeler operating, please click the following link:

www.youtube.com/watch?v=jSIrtIFLgmc