Back

SUBCRITICAL CO2 EXTRACTION SYSTEMS (428ms)

Price (excl GST): $205,500

Make: Ecoextractum

Model No: ECO-50L

Length: 2000

Width: 1000

Height: 1250

Motor: 30kW

Condition: New

Location: Lithuania

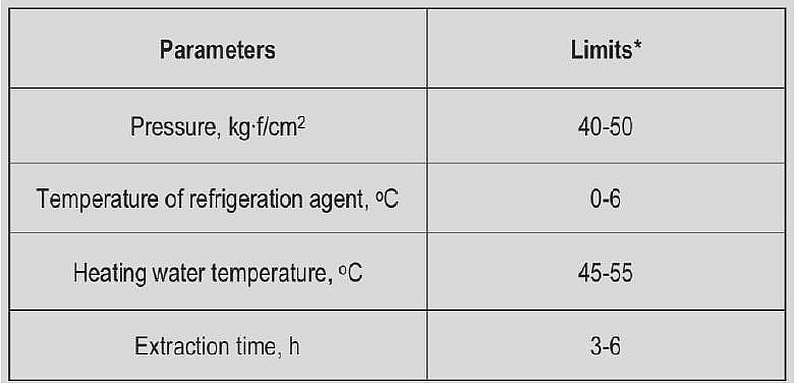

These are New Subcritical CO2 Extraction Systems which use liquid carbon dioxide as a solvent during a process that is suitable for obtaining lipophylic compounds. These conditions are applicable for maintaining active and aromatic volatiles from plants and can be used for the extraction from dried raw materials like herbs, cannabis, fruits, vegetables etc in low temperature. Subcritical (low temp, low pressure) CO2 extractions take more time and produce much smaller yields than supercritical, but they retain the essential oils, terpenes, and other sensitive chemicals within the plant. Liquid CO2 is used as a solvent during the process that is suitable for obtaining lipophylic compounds. These conditions are applicable for maintaining active and aromatic volatiles from plants. Are manufactured in stainless steel that is suitable for food industry.

CO2:

- Carbon dioxide filling. After setting temperature of refrigeration system, CO2 balloons are connected to the machine and the system is filled to the desired pressure.

- The filling of liquid CO2 vessel. While monitoring the gauge of liquid level, it is expected that liquid will reach the desired level.

Process:

- With opening one valve it is allowed for liquid CO2 flow into extraction vessel.

- Material soaking. On demand the material is kept submerged by solvent – liquid CO2.

- The beginning of the process.

- After setting temperature of the heating system, one more valve one more valve is opened and continuous (or closed) extraction cycle starts.

- Product is then released through the pipe.

Equipment set includes: high pressure refrigerator, high pressure CO2 collecting vessel, high pressure extraction vessel with pressure closure, high pressure evaporator, and overpressure relief.

Our Extractors are build for easy install and efficient use. Equipment price as well as annual usage costs (services) is less than others in the market. These do not require a large team of specialists or engineers. Just one supervisor and one (per team) operator is certified to work with high pressure equipment. You can find our technology to be used on cannabis plants. At this moment we are on to the next level to upgrade our extractors for many differing raw materials to be processed in the same unit just by changing mode.

Our units have been sold to Europe, Africa, USA & Canada and our customers use the equipment for:

• Cannabis extracts;

• Peppermint extracts;

• Cinnamon extracts;

• Black pepper extracts;

• Pine needle extracts;

• Dill seeds extracts