Back

LIQUID / SOLIDS SEPARATORS (268gr)

Price (excl GST): POA

Make: Sepcom

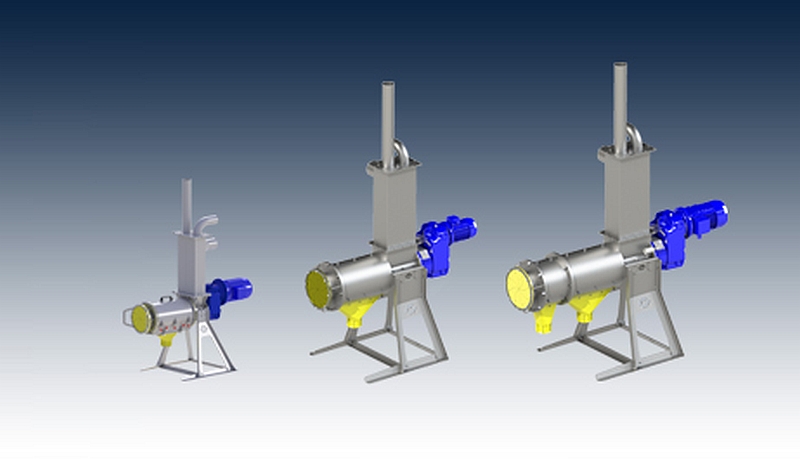

Model No: 015 / 045 / 065

Length: 1200 / 1622 / 1922

Width: 660 / 975

Height: 1200 / 2767

Motor: 3ph, 2.2/4/5.5kW

Condition: New

Location: New Zealand

Output: upto 65m³

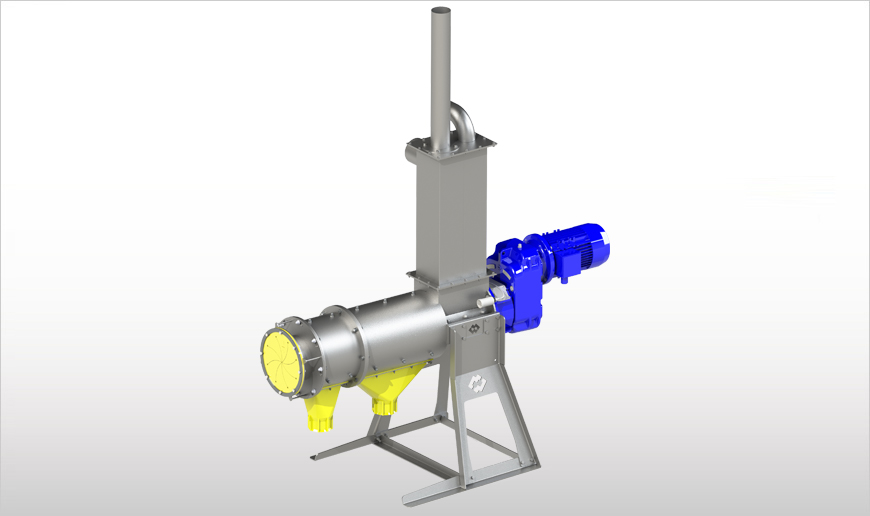

These new horizontal screw presses are designed for waste separation. Have self cleaning technopolymer screw, stainless steel sieve and stainless steel body with carbon steel support structure. Are offered in three (3x) differing models – Sepcom 015 (2.2kW power consumption) rated a maximum capacity 15 cubic metres per hour, the Sepcom 045 (4kW power consumption) rated a maximum capacity up to 45 cubic metres per hour and the Sepcom 065 (5.5kW power consumption) rated a maximum capacity up to 65 cubic metres per hour. All appear very similar, doing the same job just with different outputs.

The Sepcom horizontal screw press is an innovative solids / liquid separator. Thanks to its special features like the compensator hopper tank, the self-adjusting counter-pressure diaphragm and special screw types, a variety of materials from biogas plants, industrial processes, as well as slurry from livestock breeding can be treated. Thanks to the particular Sint engineering polymer screw design, the Sepcom can be easily adapted to various materials and applications. A specially shaped screen enables self-cleaning ensuring reduced wear.

Description:

The Sepcom horizontal screw press separator consists of a feeding section provided with a compensator tank and overflow hopper. The stainless steel casing includes a screw conveyor and a cylindrical screen basket that conveys and separates the solids from the liquid phase flowing through the screen, while the solid fraction is pushed towards the counter-pressure diaphragm outlet where a material plug forms. This enables automatic operation of the separator preventing the liquid phase from flushing through. The drive unit consists of an electric motor and a gear reducer equipped with a splined output shaft which is directly coupled to the conveyor screw.

Function:

The Sepcom horizontal is a solids-liquid separating machine based on screw conveyor technology. Performing separation by both gravity and mechanical compression, the machine is designed to separate the liquid phase from the solid phase of a wide range of materials such as sludge, sewage, manure, vegetable and fruit processing waste and, in general, solids-liquid mixtures in which the percentage of liquid inside the solids may differ considerably. The separated solid phase and liquid phase can both be easily and cheaply handled.

The separated solid phase is shovel able and easy to store/convey, can be used as bedding for animals, excellent as soil ammendant and can be marketed as an odourless non-percolating product. The separated liquid phase is easy to spread, mix and pump. Has a minimum residual sedimentation or incrustation. Is excellent for ferti-irrigation and can be used for washing out shed.

Features:

• Modular screw manufactured from anti-wear Sint engineering polymer:

• Simple in operation and cost-saving in spare parts

• Durable, high performance self-cleaning screen basket

• Suitable for continuous duty

Options:

• Various types of diaphragm outlet

• Various types of Sint engineering polymer screws

• Various screen basket sizes

• Input tank with pump and two (2x) level sensors

• Electrical control panel

• Steel structure

Please click the following links to view videos:

https://youtu.be/ErqNW3QXZSg

https://youtu.be/i9FS1HbuPKk - treatment of pulp in a paper mill

https://youtu.be/PbpZGlQhuhQ - pig farm application

Measurements:

Sepcom 015 - 1200mm long x 660mm wide x 1200mm high

Sepcom 045 - 1662mm long x 975mm wide x 2767mm high

Sepcom 065 - 1962mm long x 975mm wide x 2767mm high

Prices including 12 months warranty on parts and workmanship but excluding freight from Auckland for NZ purchasers and installation costs:

015 model - $33,000.00 plus GST

045 model - $52,500.00 plus GST

065 model - $58,500.00 plus GST