Back

SEMI AUTOMATIC ISOBARIC FILLER & CROWNER (269fi)

Price (excl GST): POA

Make: Compactblock

Model No: 661

Motor: 1ph, 0.37KW

Condition: New

Location: UK

Output: upto 500bph

The seller has stated:- We have an excellent rinser/filler/crowner called the COMPACTBLOCK which is a superb solution for breweries looking to bottle their beers, Kombucha or ciders at an entry level stage. It is an excellent solution for small brewers wanting to package their beers affordably and still have an excellent finished product with long shelf life.

The COMPACTBLOCK offers double pre-evacuation of air from the glass bottles, double CO² flushing of the bottles before counter-pressure filling, and also injection of inert gas (usually CO²) in the neck space prior to capping so that we remove as much of the oxygen from the bottle as possible before it is closed, which means the dissolved oxygen levels are as low as possible. Our clients have recorded dissolved oxygen levels of around 40-60 PPB in the bottles after filling and twin head crown capping with our COMPACTBLOCK

It is a very flexible system that will allow you to work different size bottles or cans with a simple manual adjustment. No change parts are required apart from different fill level tubes for each different fill level you may require.

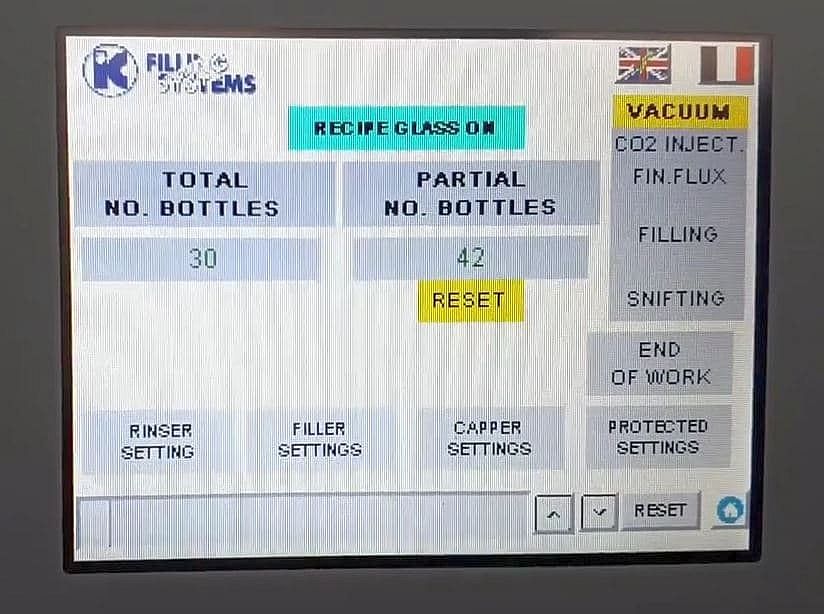

This filling cycle is done using electronic filling valves and the cycles are controlled through a 3 inch colour PLC touch screen control panel. This control panel offers you the possibility of remote access software assistance in case you need software support by one of our specialist technicians online.

Our bottle rinser has a “no bottle – no rinse” system included as standard.

Our machines are produced in Italy, we do not use any parts for the far east at all, and all materials are brought in from Germany and Italy so your money would be buying you a first grade top quality piece of equipment.

Here you can see a video of our Compactblocks in operation:

www.youtube.com/watch?v=iNijQ8Pym9I&;t=9s

Please also note that there is a new feature available with the COMPACTBLOCK which allows you to fill and seam aluminium cans as well with the purchase of some additional accessories, allowing you total flexibility to package your products in various types of containers with minimal changeover requirements.

There is a video of our semi-automatic labeller with date coder in operation that you can see here:

www.youtube.com/watch?v=i8rJg1PoRko&;t=21s

Product Non Carbonated / carbonated beverages production speed up to 500 bph on 330ml (depending on operator ability, bottle size & fill temp)

Bottle sizes possible 370mm height bottles - 150mm diameter bottle.

Air consumption: 180 litres of air per minute @ 6 bar pressure

Fill temperature: 0-2 degrees Celcius

Structure is painted steel covered with stainless steel plates on 4 lockable wheels for easy moving.

Easy clean stainless steel base with recessed working area to prevent product & water spillage.

6 electro-pneumatic counter-pressure filling valves (diameter 15mm)

Easy access back doors for filler maintenance

Glass vessel on side of filler to prevent flooding of vacuum pump

CIP system with stainless steel pneumatic pump.

Accessories to also rinse, fill and seam aluminium cans can also be incorporated at additional cost.

PLEASE NOTE: semi automatic or automatic (front, back and neck) self adhesive labellers (along with hot stamp date coders for the labels) can also be supplied along with inline carbonators.