Back

CHEESE BLOCK CUTTERS (087da)

Price (excl GST): POA

Make: PPT Engineering

Model No: PPT 20kg BC

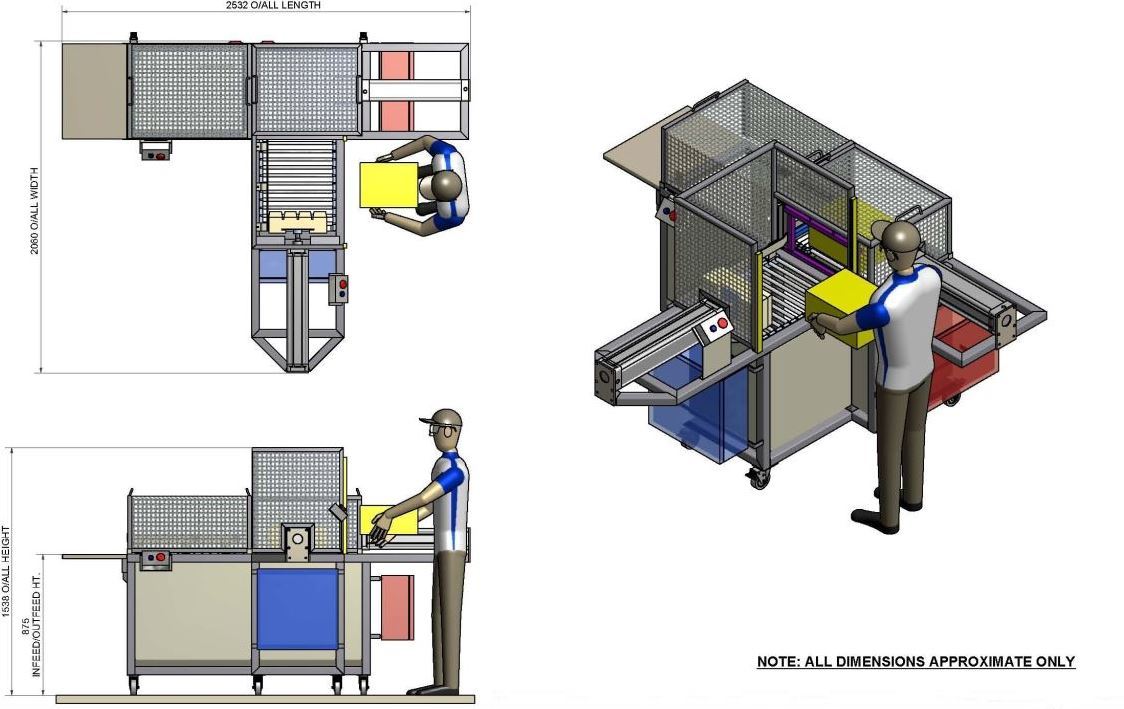

Length: 2000

Width: 2000

Height: 1800

Motor: 1ph, air

Condition: New

Location: Australia

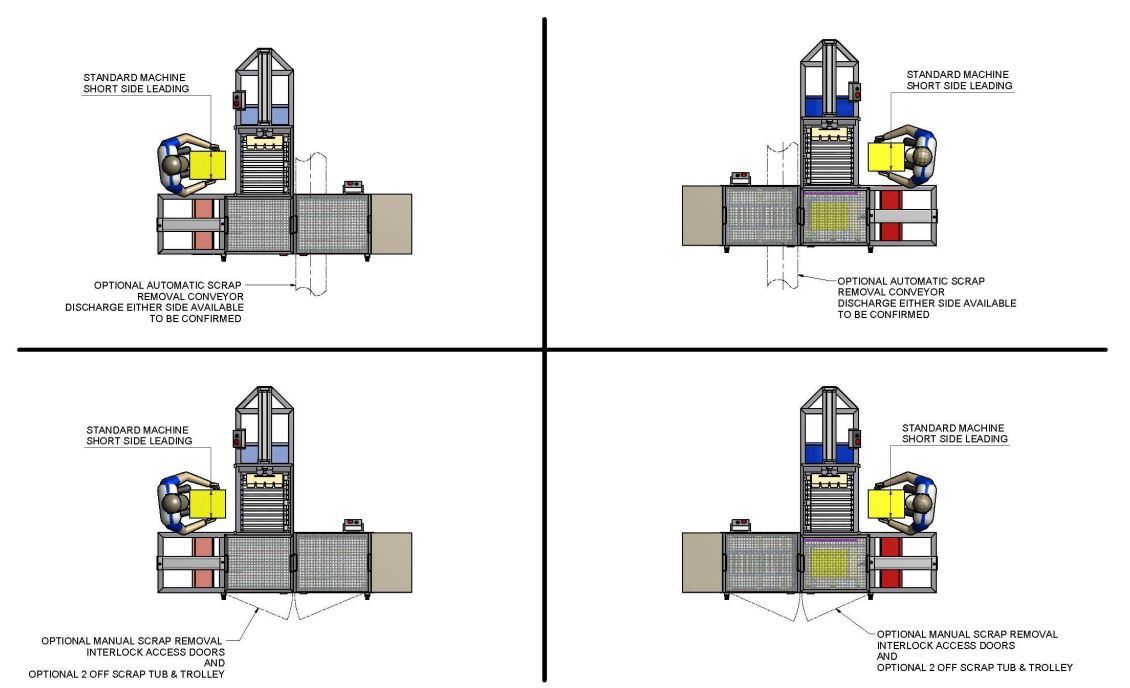

These NEW stainless steel block cutting machines are designed for cutting 20kg cheese blocks into pre selected, fixed weights from 150 grams to 2.5 kgs (30mm x 30mm cube is the smallest cube they can produce). The machines can be manual loading or semi auto with power conveyor in feed. This machine will be designed to cut from 360mm x 280mm x 180mm high, 20 kg blocks of cheddar. Sizes to be set to get the best yield from a 20 kg block.

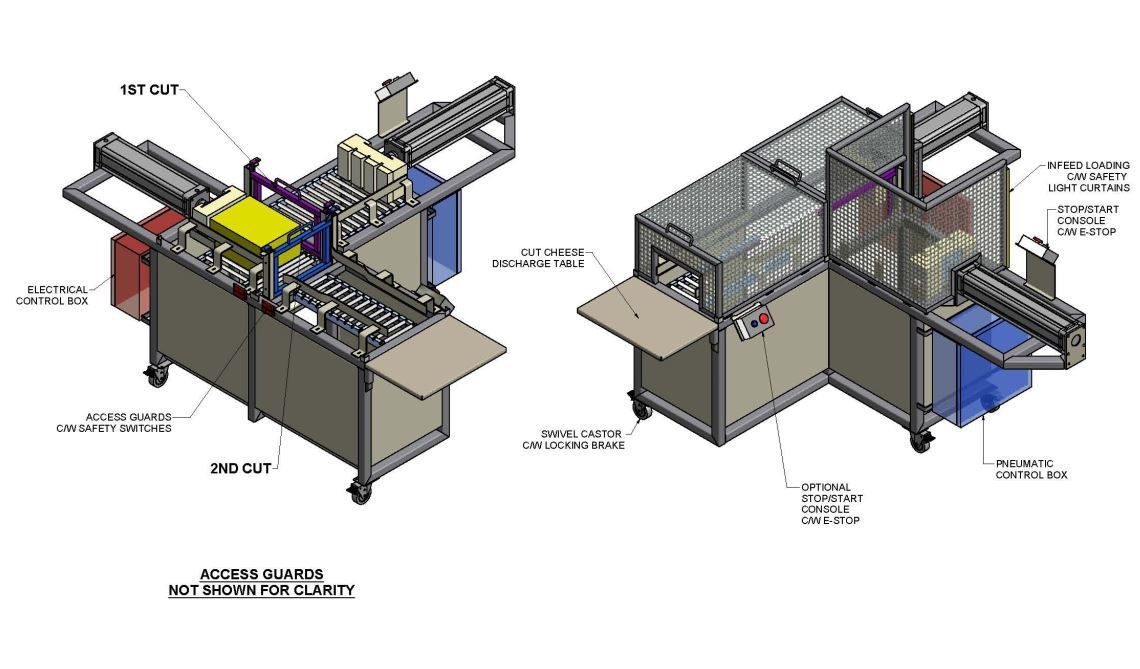

They are built and designed to AS4024 and AS3000 safety standards to clients requirements. The manufacturer will provide a full days training on setup and maintenance. This machine is an L shape with 2 pneumatic cylinders pushing in an X to Y system. The cheese blocks are loaded via guarded loading area into the machine (SICK or Omron Cat 4 light curtains) the cheese will be cut one way and then cut again at 90 degree to the required size going through wire harp frames. Cylinders to be fitted with reed switches, interfaced with the PLC for control.

There is 1 guarded door for maintenance access and removing harp frames and pusher blocks for cleaning, this guard will be electrically interlocked with a magnetic guard switch and holding latch.

Two (2x) Harp frames will be supplied with the machine to cut sizes TBA. (Note this is a 1 off set for a cut size, if you want to cut other sizes you will need more harp frames and blocks).

Has full 304 stainless steel construction, and stainless steel castors 100mm diameter swivel locking. Is wash down to IP65. All pneumatic parts to be Festo Brand, spare parts list to be supplied. Pneumatic and electrical drawings to be supplied.

Also features:

Safety system AS 4024 to Cat 3. Machine is fitted with a Festo Monitored Duel redundancy valve, this will dump all air supply should the guards be opened at any time. Electrical safety relay SICK brand, all electrical work to AS3000. 1 x Omron Micro PLC.

Stainless steel MCC cabinet complete with padlock able main switch, 24V DC power supply, 1 only safety relay, 1 only Emergency Stop/Reset Buttons and stainless steel enclosures, 2 only magnetic guard switches. Stainless steel cabinet to house all pneumatic controls, regulator, duel redundancy valve, etc.

These cutters require electrical (240V, 10 amp) supply along with 6 bar (compressed air) supply.

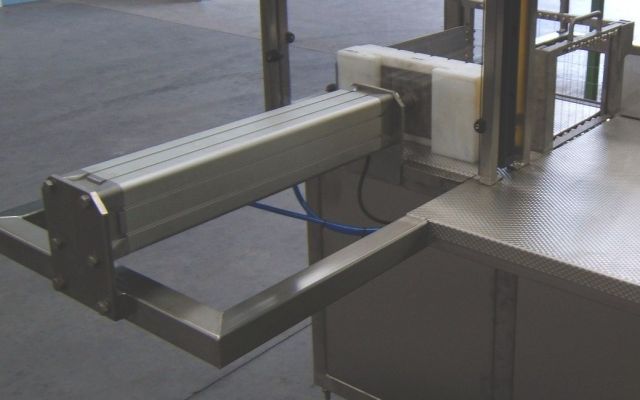

The out feed areas of cutter are small roller conveyors to allow the product to flow freely and not stick to the bottom base of the cutting machine.

To cut different weights, you will require a harp frame for the first and second cut to each weight, you will also require 1st cut pusher blocks. These blocks have a dove tail slip on fit and can be removed very easily for change over and cleaning. If you require different size cutting frames, please allow AUD$2000 per set, (1 set of one harp frame and one pusher block) plus freight.

Machine will be crated in a wooden box for delivery.