Back

CITRUS JUICE EXTRACTORS (036fr)

Price (excl GST): POA

Motor: 3kW / 5.5kW

Condition: New

Location: Italy

Output: upto 15,000/hr

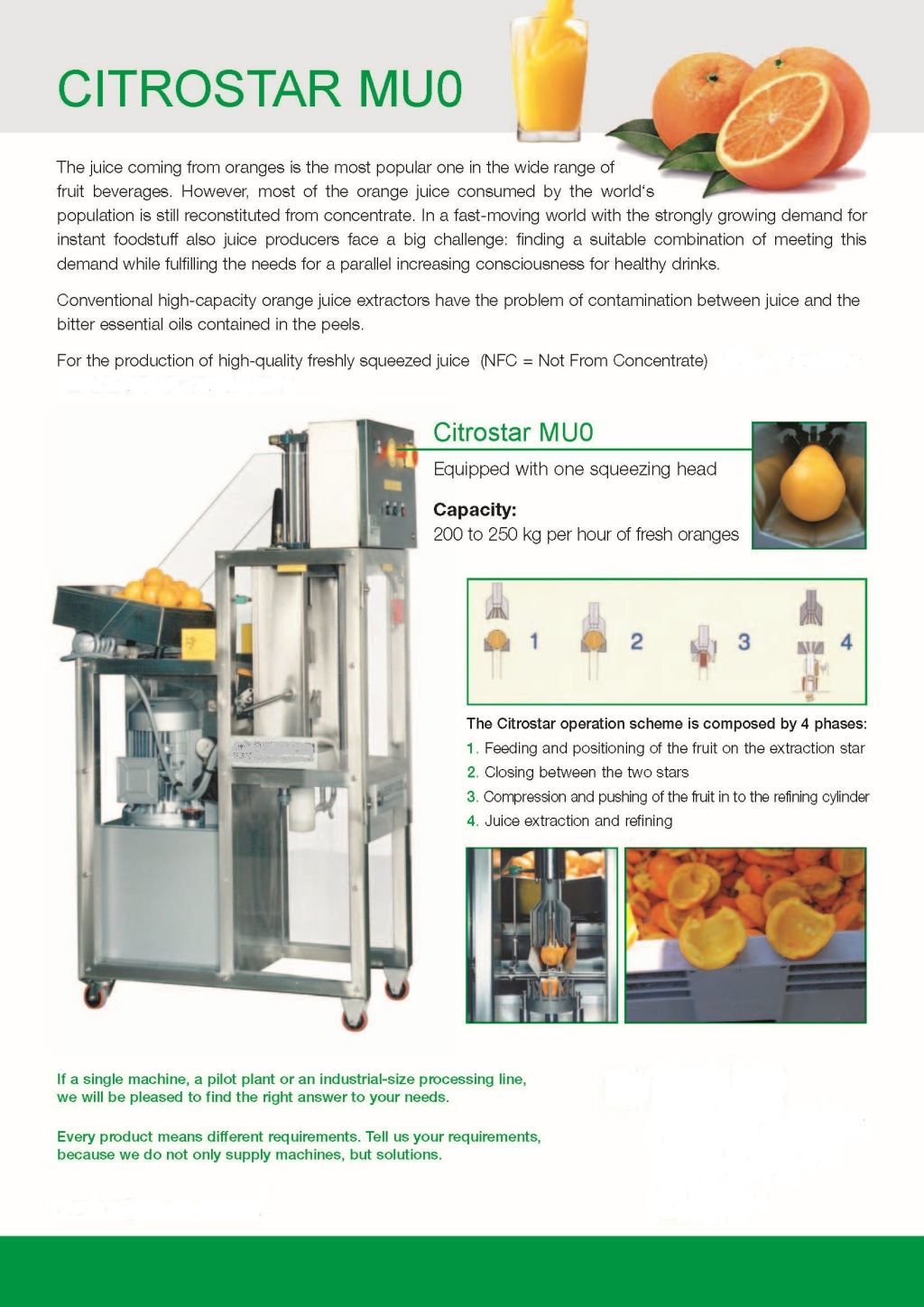

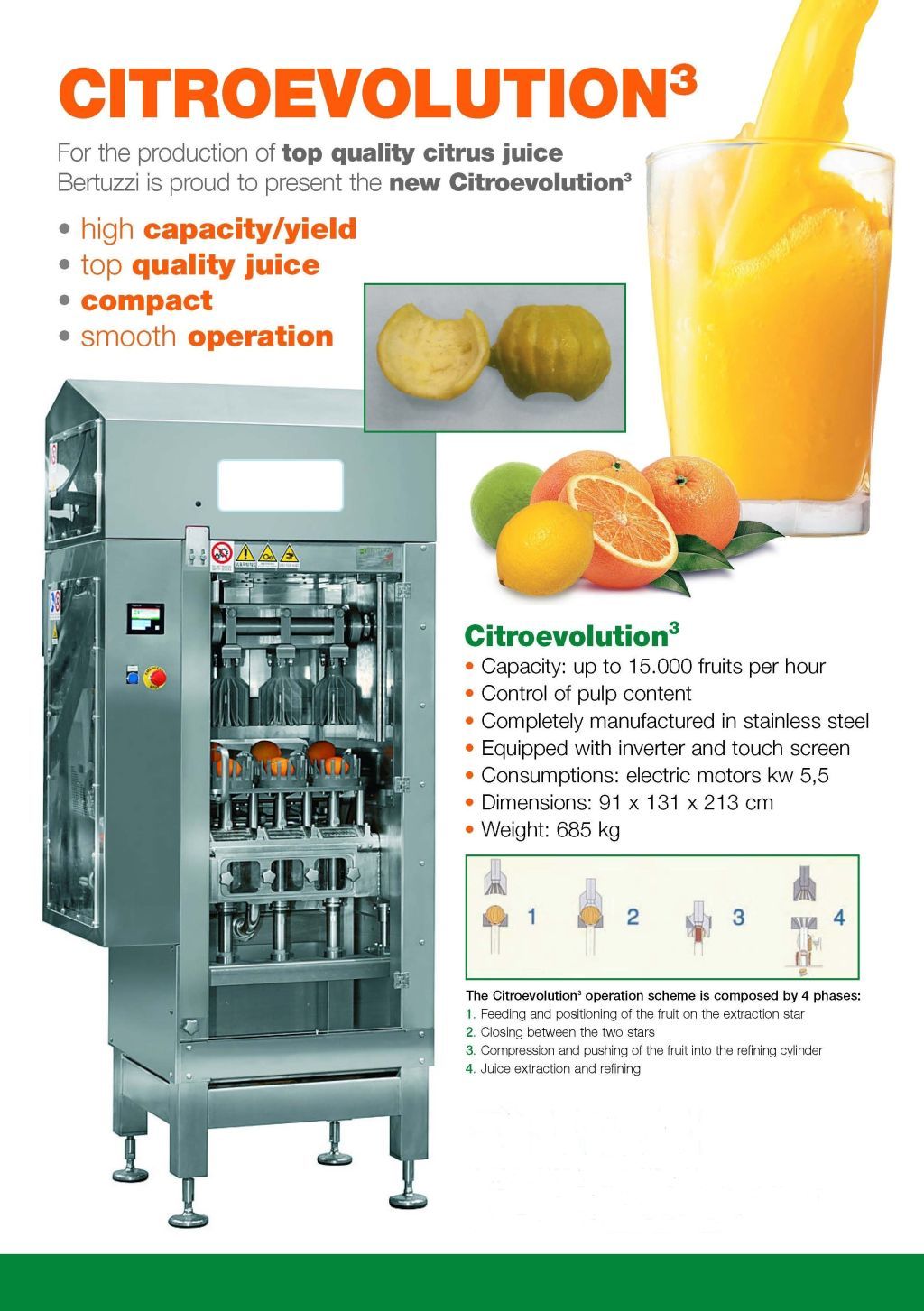

This extractor produces high quality fresh juice from whole fruit. It has been designed to extract juice out of citrus with strong, elastic skin such as oranges, tangerines and lemons. It is available in two models, either one head or three heads. The single head model is particularly suitable for research centres, food-industry labs, training centres, and small processors and has a capacity of 20 to 25 pieces/min. The 3 head model is rated an approx capacity of 10,000 pieces/hour corresponding to around 1650 kg/hr depending on fruit size (normally considered that 6 pieces = 1 kg) and at maximum of up to 15,000 pieces per hour.

The juice extraction is obtained from the centre of the fruit by means of centripetal compression carried out by penetrating star shaped cups. Fruit is therefore pierced through and pressed into the squeezing and refining cylinders allowing separation of juice from skin and pulp. The special squeezing system allows extracting pure juice with virtually no contamination by essential oils and other substances contained in the flavedo and albedo. The machine therefore produces a high quality fresh drinkable juice.

This machine is suitable for fruit ranging from 40 to 90mm in diameter. For the best performance fruit should be previously graded. The equipment consists of a main machine frame constructed of AISI 304 stainless steel with plexi-glass doors. All safety guards may be easily and completely opened for ease of cleaning and maintenance, a rotary feeding system transferring fruit from loading section into squeezing section, one pair of squeezing cups per squeezing head for juice extraction made of AISI 304 stainless steel. The cups are complete with a piercing cylinder, a refining cylinder, a pulp discharge chamber and squeezed skin discharge slide, pressure adjustment tools. A hydraulic drive with dedicated power unit (one-head model). A juice collecting container easy to open and inspect made of stainless steel and may be directly connected with an in-line juice tank or refining machine. A main switch-board with stainless steel housing comes with the system. All parts coming into contact with fruit are made of AISI 304 stainless steel, except for some parts that due to engineering and operating needs, are made of other food-grade material.

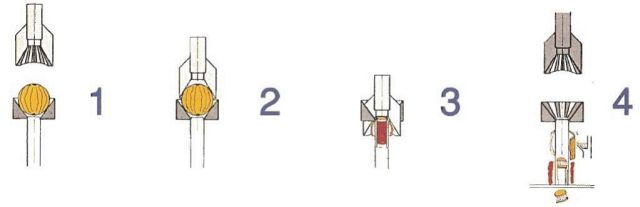

The operating cycle consists of four stages:

1) Fruit feeding and positioning onto the squeezing cups,

2) Fruit being closed by the cup pair,

3) Fruit pressing into the refining cylinder, and finally

4) Juice extraction and refining with separation of the skin for possible collection of essential oils.

The units have the following electrical power requirements of 5.5kW, 380V, 50Hz for the 3 head model and 3kW, 380V, 50Hz for the single head model. Please enquire for specification sheets shown in the photos in a larger format if required.