Back

BIN TIPPERS (552pa)

Price (excl GST): POA

Make: Dumpmaster

Condition: New

Location: New Zealand

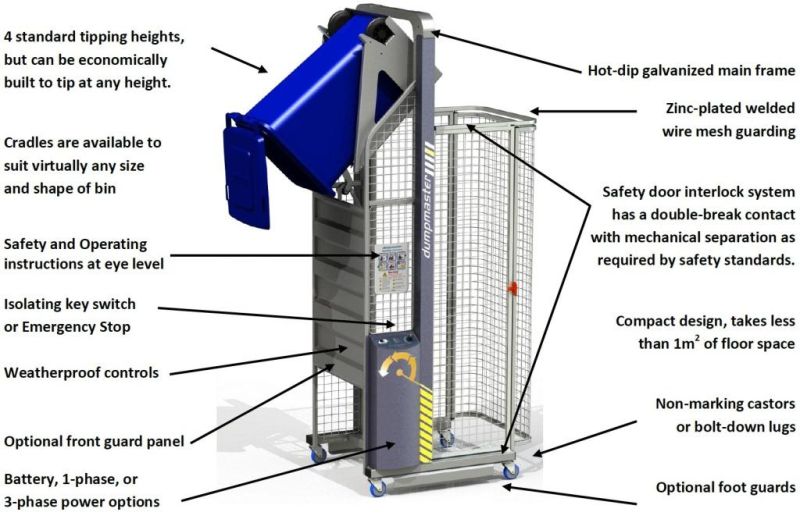

These bin-tippers have a unique tipping action whereby bins are lifted straight up, then gently rolled forward around the lip of the skip or hopper being emptied into. Benefits of this design include a very small footprint, and a wide range of tipping heights available (from 700mm to 6 metres or more). Also, Dumpmasters may be mounted on four castors with no loss of stability. There are four standard tipping heights but can be economically built to tip at any height. Cradles are available to suit virtually any size and shape of bin. Safety and operating instructions are at eye level. They have an isolating key switch or emergency stop. Have weatherproof controls. Optional front guard panel. Battery, 1 phase, or 3 phase power options. Weight capacity of up to 250kg (or 300kg with small modifications).

Standard Dumpmasters have a galvanised frame and cradle, and are virtually maintenance-free. Dumpmasters are available either with full stainless steel construction, or with selected components from stainless-steel for critical hygiene areas or corrosive environments. Standard drums and bins do not require clamping, simply place on the cradle and press the Raise button. Dumpmasters are highly versatile and can be used in numerous applications, ranging from emptying rubbish bins into skips to pouring food ingredients into hoppers or mixers.

Hot-dip galvanized main frame, zinc-plated welded wire mesh guarding. Safety door interlock system has a double-break contact with mechanical separation as required by safety standards. Compact design, takes less than one square metre of floor space. Non-marking castors or bolt-down lugs and optional foot guards.

Wide Series Dumpmasters are available with cradles to suit a range of larger bins, including 660L, 1000 / 1100L wheelie bins, or square and rectangular bins. Attachments are available to enable multiple bin sizes to be tipped, for example a cradle for tipping 1100L bins can be fitted with auxiliary catches to enable all standard wheelie bins from 80 litres up to 660 litres to be tipped as well. No adjustment is required for tipping the different sizes.

A range of accessories is available to provide additional features or functionality for Dumpmaster bin-tippers. Many of these features can be retro-fitted to existing machines: A pressed steel panel is available for the front of standard series Dumpmasters. Note that this face is normally up against the bin being tipped into, but in some cases is required to provide additional protection. The door on standard machines in hinged on the right hand side. Left-hinged doors are available if specified at the time of ordering. A polycarbonate guard screen is available to protect the operator from glass or chemical splashes. PET-G guarding panels are available in place of the standard welded wire mesh guards. PET-G is virtually unbreakable and is used for manufacturing soft-drink bottles, but is more difficult to keep looking clean than wire mesh. The standard mesh is 50 x 4mm, which allows fingers through but no more. Smaller mesh is available if required.

Dumpmasters can be powered by 1 phase, 3 phase, battery, (or even compressed-air for use in hazardous areas). In all cases, the power supply is used to run a motor, which in turn drives a hydraulic pump. The lifting pressure and speed are accurately controlled, resulting in a safe, smooth operation. An auto-cycle controller is available for mains-powered machines only. This unit connects directly into a standard wiring loom, and has 3 potentiometers to adjust the raise, hold, and lower times. For more complex functions (eg interacting with other equipment) a programmable relay is available. The controls can be mounted at the door end of the machine so the operator is well away from the product as it empties. As a further safety measure, dual controls can be fitted, requiring the use of both hands to operate. The door switch system on standard Dumpmasters is safe and reliable, and uses a double-break mechanical contact as required by safety standards. However, it is not a certified system. Approved door switches can be fitted if required.

Additional controls can be fitted on the opposite side to standard. Several options are available. The simplest and cheapest method is to have the Raise / Lower buttons mounted in the vertical cover on the opposite side. The standard controls can be retained as well if desired. They can be mounted in any of the 3 faces. An Emergency Stop or key switch can also be provided. Steel covers can be fitted to the both sides. The power pack normally remains in the standard side. Note: the power-pack covers can be fitted on the right-hand side instead of the left-hand side. This is not generally recommended, as the entire machine needs to be built to the opposite hand. Two standard frame-mounted chutes are available for situations where the Dumpmaster cannot go right up against the skip, bin, or hopper. Note that the tipping height generally needs to be increased to allow for the slope of the chute. The chutes attach easily with two bolts, and can be folded up out of the way when not in use. Custom chutes are also available. The Bin-Hook kit attaches quickly and easily to most Dumpmasters, allowing them to be attached securely to a bin or skip. Several different versions are available, to suit different bins. The Hook frame can be simply mounted at any height, without fastenings.

Dumpmasters are available either completely constructed from stainless steel, or with selected components made from stainless steel. If the Dumpmaster is to be used in a corrosive environment, nickel-plated lifting chains can be supplied. These offer a similar level of corrosion-resistance to stainless-steel while retaining the strength of standard chains.

Where product needs to be accurately weighed, platform scales can be provided to fit under the cradle. The weight of the cradle, bin, and product is recorded before emptying, then the bin and cradle are weighed again after emptying; the difference is obviously the weight of the product. The cradle does sit slightly off the ground, and a ramp is provided with the scale kit. The Raise/Lower, key switch, and Emergency Stop switches are rated to IP66. Motors are rated to IP54 but are mounted inside a steel cover which provides additional protection. Four 100mm swivel castors with Blue Resilex wheels (2 with brake). Pressure-compensating valve to regulate lowering speed and pressure-relief valve to limit lifting capacity.